Gouge Jig SVD-185.

Multi Jig SVS-50.

This patented Turning Tool Setter perfects the Tormek Sharpening System for woodturning tools. It enables you to exactly create and replicate the edge on your bowl and spindle gouges as well as on your flat or oval skews with either a straight or a curved edge. The Setter works in conjunction with the Gouge Jig SVD-185 and the Multi Jig SVS-50.

The strength of the TTS-100 Setter is that it works irrespectively of the stone diameter. You always get exactly the same edge angle – even as the stone decreases in diameter. The Turning Tool Setter works equally well when setting the edge angle on the leather honing wheel.

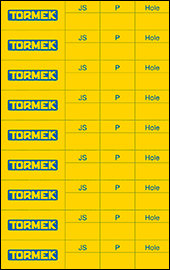

Three factors determine the shape of a gouge or a skew; by controlling them and repeating them at each sharpening you will get an exact replication of the shape every time.

SVD-185 Gouge Jig

|

SVS-50 Multi Jig

|

Jig Setting JS |

|

|

|

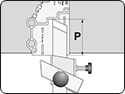

Protrusion P |

|

|

|

Universal Support position A or B |

You will find suitable geometries on the Tormek Selection Chart below which also is available as a PDF. These geometries, i.e. the shape and edge angle, are recommended by experienced woodturners and recognized woodturning training workshops around the world, e.g. Craft Supplies in the USA and Drechselstube Neckarsteinach in Germany.

Since a tool can have an unlimited number of combinations of shapes and edge angles, a new tool has a more or less different shape compared to any of the shapes on the chart. Therefore, you firstly need to shape your tool to one of these geometries; then the following sharpenings will be an easy task and done in less than a minute.

Stick to the shape you have selected and do not switch from one shape to another. Then you will get the full benefit of the Tormek TTS-100 Setter, since you can instantly replicate exactly the same shape every time. Should you need a different shape, then buy another tool and grind it to your alternative shape. This way of working will give you more time for turning and fewer interruptions for shaping and sharpening.

Note the settings on a Profile Label, which comes with the TTS-100 setter and put it on the ferrule of the tool. Now you have control of the three factors and you can exactly replicate them every time.

For detailed instructions on shaping and sharpening gouges and skews, see the chapters SVD-185 and SVS-50 from the Tormek Handbook. These can also be downloaded from www.tormek.com.

The Bowl Gouge Jig SVD-185 and the Multi Jig SVS‑50 are supplied with 9 Profile Labels.

The PL-01 set contains 9 extra labels so you can record your favourite profiles on all your bowl gouges, spindle gouges and skews.

A distinction should be made between the shaping and sharpening of a tool. When shaping you remove steel to achieve the shape and edge angle you want. When sharpening you just touch up the edge of an existing shape to renew the sharpness. The strength of the Tormek method is in the sharpening, which is carried out with an exact replication of both the shape and the edge angle. Since so little steel is removed – you just touch up the edge – the Tormek method is very fast.

Shaping the tool, which is normally a once only job, can take from 10 to 20 minutes depending on the size of the tool and how much steel you need to remove. The shaping can comprise a change of the skew angle on a chisel or the length of the wings on a gouge as well as a change of the edge angle.

If you need to change the shape considerably needing much steel removal, the initial rough shaping can be done on a high speed grinder, which removes steel faster. However you must be careful so you do not overheat the edge. With high speed grinding, you are easily tempted to speed up the grinding by pressing the tool too hard towards the grinding wheel. HSS steel stands higher temperatures than carbon steel, but there is still a risk that the very outer tip of the edge, which is very thin, will be overheated.

The need for cautious steel removal and frequent cooling in water reduces the difference in time between shaping on a high-speed dry grinder and on the slow running Tormek water-cooled grindstone. The extra minutes it might take on the Tormek for the initial shaping are worth spending, since you will not risk changing the properties of the steel, which ensures that the tool stays sharp much longer. Bear in mind that you shape the tool only once.

The technique when using a high-speed dry grinder is different from when working with a water-cooled slow running grinder. Here are some simple but useful tips.